| Technical

parameters - Specifications.

|

| Wind

turbine. |

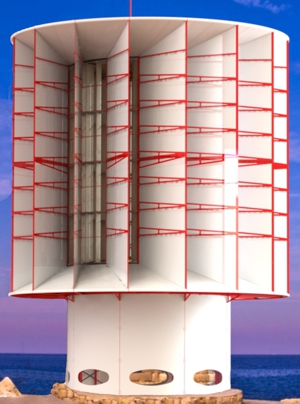

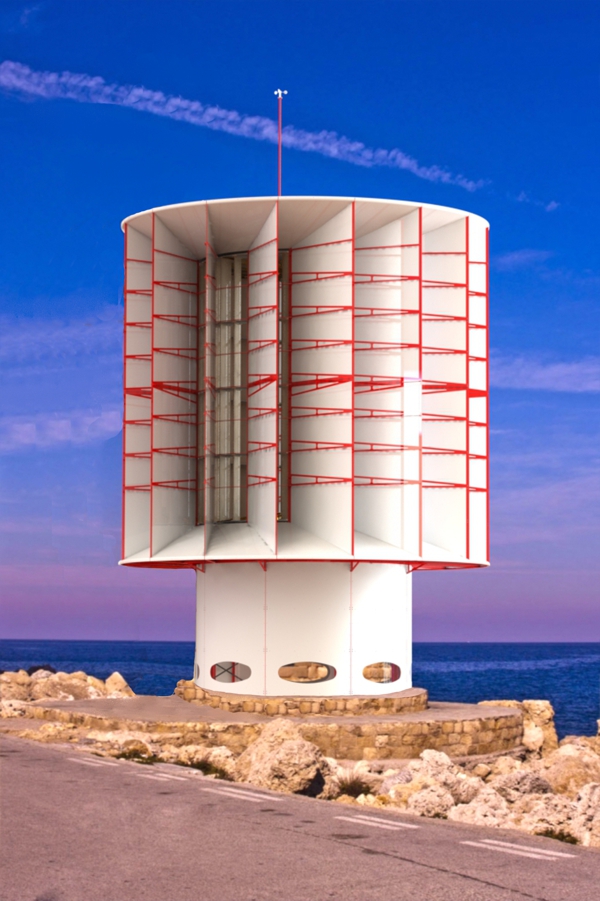

| Model: |

"Iasos

IIIa" |

Individual

wind turbine sectors

|

| Nominal

power: |

7

Kva |

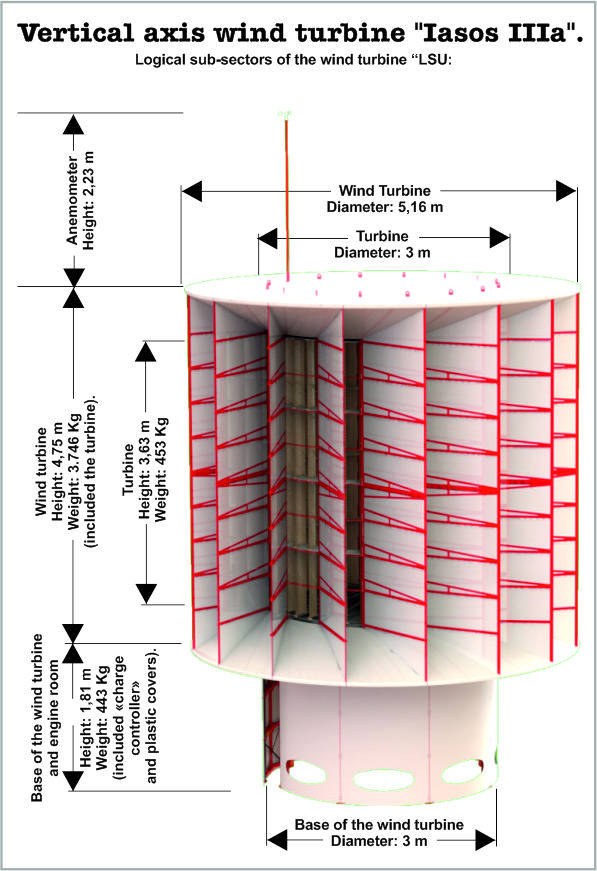

| Size

of the base of the wind turbine:

|

| Diameter: |

2,956

m |

| Height: |

1,910

m |

| Weight: |

1.623

Kg |

Sizes

of the wind turbine (Base not included): |

| Diameter: |

5,026

m |

| Height: |

4,830

m |

| Weight: |

3.360

Kg |

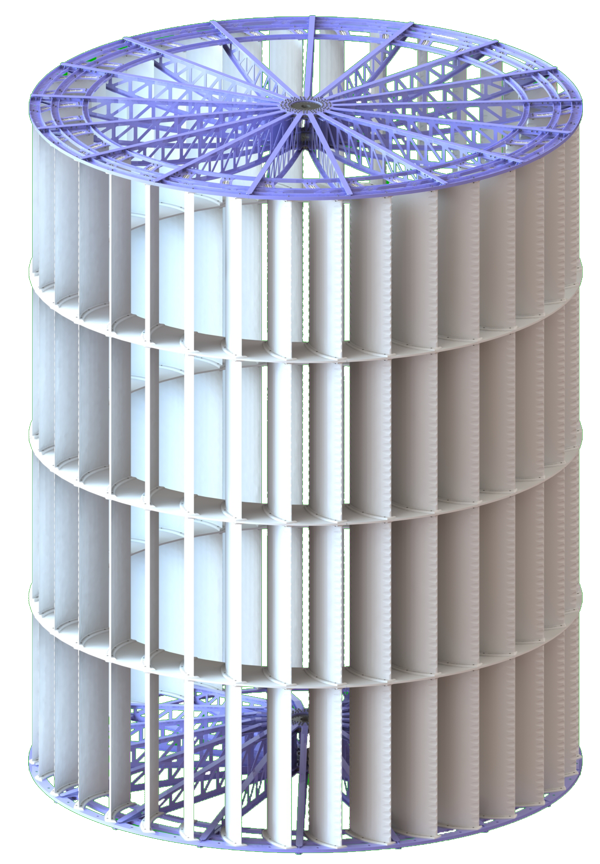

Sizes

of turbine (rotor): |

| Diameter: |

2,940

m |

| Height: |

3,700

m |

| Weight: |

666,9

Kg |

Sizes

of the wind turbine as a whole: |

| Diameter: |

5,160

m |

| Height: |

6,757

m |

| Weight: |

4.982,7

Kg |

| Surface,

vertical projection of the wind turbine, into the wind: (including diffusers,

not including the base of the wind turbine) |

32,6

m2 |

Wind

speeds at which the wind turbine can generate electricity: |

|

| From: |

0,9

m/s |

| To:

(with full load) |

12,5

m/s |

| To:

(at 80% load or less) |

13

m/s |

| Noise

during operation: |

0

db |

| Vibrations

during operation: |

Zero |

| Permissible

operating temperatures: |

| From: |

-

14 C0 |

| To: |

+

48 C0 |

| Permissible

operating relative humidity: |

92% |

| Aerodynamic

factor: (depending on wind speed) |

| Minimum: |

7,29 |

| Maximum: |

25,67 |

| Safety

factor: |

5 |

| Frame

construction material: |

Q235

JS,

DIN 1.0037

A36 ASTM |

| Cutting

and processing method: |

CNC

Laser |

| Welding

method: |

MIG,

TIG, Laser |

| Cleaning

method before painting: |

Phosphating |

| Dye

method: |

Electrostatic

paint of two consecutive layers |

| Maximum

wind load: |

50,898

N |

| Maximum

wind speed: |

160

Km/h |

| Maximum

snow load: |

7,35

kN/m2 |

| Maximum

permissible weight on the roof: |

1.000

Kg |

| Maximum

permissible weight on the lower surface of the turbine chamber: |

231

Kg |

| Number

of wind turbine base pylons: |

8 |

|

| Total

surface area of flanges in contact with the ground: |

3.200

cm2 |

| Standards

under which operation was tested: |

| Electromagnetic

compatibility, emissions: |

EN

61000 - 6 - 3 |

| Electromagnetic

compatibility, immunity: |

EN

61000 - 6 - 1 |

| Box

for trasportation: |

| An

entire container size 20 ft is used for transportation.

|

| Plastic

components. |

| Plastic

parts manufacturing material: |

PVC

1,67 %, 6 % UV |

| Cutting

and processing method: |

CNC

Laser |

| Method

of making turbine blades: |

Extruder |

| Steel

components. |

| Shafts

construction material: |

20CrMoTi

20MnCr5 (1,7147)

|

| Fastener

construction material (screws, nuts, etc.): |

AISI

304 (SS) |

| Turbine

(rotor). |

| Number

of turbine blades: |

136 |

| Total

positive blades area: |

42,432

m2 |

| Total

area of blades active in the wind: |

31,204

m2 |

| Surface,

vertical projection of the turbine, into the wind: |

10,902

m2 |

| Maximum

operational speed of rotation of the turbine: |

26,7

rpm |

| Maximum

permissible speed of rotation of the turbine: |

100

rpm |

|

| Maximum

turbine torque: |

8.383

Nm |

| Turbine

speed control techniques: |

| Dump

load: |

Yes |

Turbine

stopping techniques: (braking) |

| Manual

brake: |

Yes |

| Manual

electric brake: |

Yes |

| Dump

load: |

Yes |

| Turbine

rotation direction: |

Clockwise |

Blades

material: |

PVC

1,67 %, 6 % UV |

| Turbine

pulleys. |

| Construction

material of the turbine pulleys: |

Q235

JS,

DIN 1.0037

A36 ASTM |

| Cutting

and processing method: |

CNC

Laser |

| Welding

method: |

MIG,

TIG, Laser |

| Cleaning

method before painting: |

Phosphating |

| Dye

method: |

Electrostatic

paint of two consecutive layers |

|

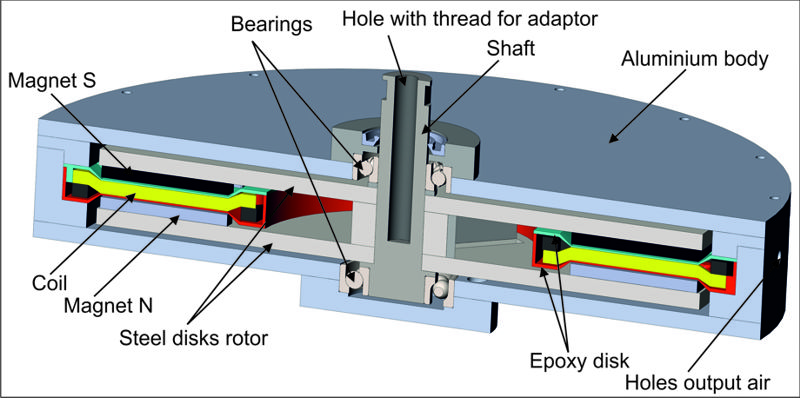

Generators

model H8035. |

| Number

of generators installed: |

2 |

| Installed

generator model: |

Ç8035 |

| Type

of generator installed: |

Coreless

permanent magnet generator |

| Rated

generator power: |

3,5

KVA each |

| Rated

output voltage of generator (phase voltage): |

180

ACV |

| Rated

rotation speed: |

300

rpm |

| Generator

power factor: (cosö) |

0,9851 |

|

| Maximum

torque supplied by the generator: |

236,11

Nm |

| Maximum

generator efficiency: |

94,79% |

| Minimum

generator efficiency: |

75,26

% |

| Connection

of coils, type: |

Y |

| Phases: |

Three |

| Generator

weight: |

57

Kg |

"Master

controller". |

|

The

"Master controller" automatically checks and adjusts all the

operating parameters of the wind turbine, except those that concern the

two generators individually. Includes: |

| 1.

Digital anemometer. |

| 2.

Automatic power source selection switch. |

| 3.

Digital displays of all operating parameters. |

|

| 4.

Digital regulators of the operating parameters of the wind turbine. |

| 5.

"Extra load" function. |

| "Charger

controller" model H9035. |

| Number

of "charger controllers" installed: |

2 |

| Model

of "charger

controller": |

H9035 |

| Rated

power of "charger

controller": |

3,5

Kw |

| Rated

output voltage of "charger

controller": |

48

DCV |

| Types

and number of inputs: |

| Three

phase AC: |

2

input |

| Battery

charging methods: |

| Bulk: |

Yes |

|

| Absorption: |

Yes |

| Buck: |

Yes |

| Functions

of "charger

controller": |

| MPPT

(Maximum Power Point Tracking) |

Yes |

| MCU |

Yes |

| DUMP

LOAD |

2

Kw |

| BOOST |

Yes |

| BUCK |

Yes |

| HYBRID

SYSTEM |

Yes |

| "Gear

box" model G10119. |

| Power

transmission installed: |

Gear

box |

| Model: |

G10119 |

| Power

transmission ratio: |

1

X 11,9 |

| Rated

power: |

31

Kw |