Phone:+86 13333092057 Email: iasos@iasos.eu

Phone:

+30 6999398373 Email: coyote@iasos.eu

|

|

|

|

Phone:+86 13333092057 Email: iasos@iasos.eu |

Phone:

+30 6999398373 Email: coyote@iasos.eu |

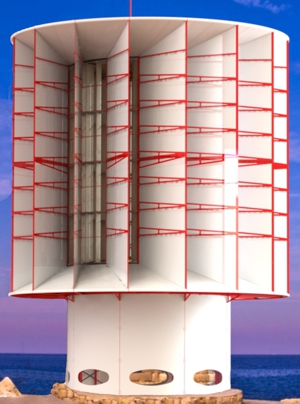

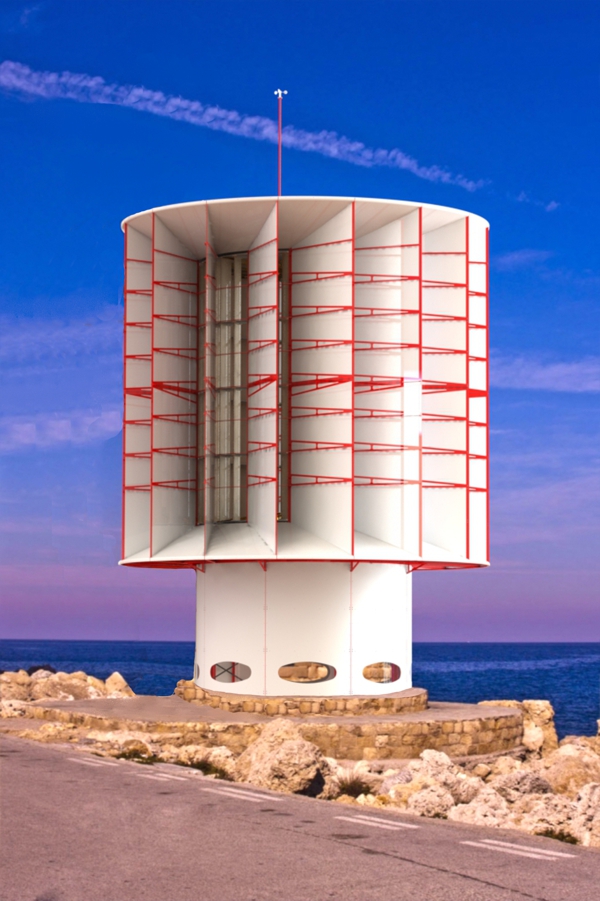

| Vertical

axis wind turbine:

"Iasos IIIa". |

Nominal

power: 7 KVA |

| Download |

|

||

| Equipment

included in the wind turbine

|

|

Nominal

power: 3,5 KVA |

2

pieces |

| Generator

specifications: |

|

| Type: |

Coreless,

axial with permanent

magnets |

| Rated

rotation speed: |

300

rpm |

| Rated

output voltage: |

180

acv |

| Type

coil connection: |

Y |

| Coils

per phase: |

15 |

| Phases: |

Three |

| Pair

of magnets: |

20 |

| Shell

construction material: |

Aluminum |

| Shaft

diameter: |

45

mm |

| Weight: |

54

Kg |

|

Nominal

power: 7 KW |

| The

"charger controller" is used to convert the electric current

produced by the generator into an electric current suitable for charging

the batteries. The buyer should make all the necessary settings on the

"charger controller" so that its operation is efficient, depending

on the available batteries. This "charger controller" has the following technical characteristics: - It has an electronic PWM device to protect the wind turbine from over speed, over voltage and over power. - It has the ability to automatically calculate the maximum capacity of the batteries and automatically calculate the charging rate and maximum charging current. - It is equipped, in addition to the automatic, digitally adjustable, electric braking system and with an autonomous braking system, activated by the user with a switch. - It has integrated BOOST and DUCK technology. The generator installed in the wind turbine has a variable output voltage, depending on the intensity of the wind. When the wind is not strong and the generator voltage is lower than the battery voltage, the "charger controller" automatically increases the voltage to be suitable for charging the batteries (BOOST configuration). Accordingly, when the wind is strong and the voltage of the generator is higher than the voltage of the batteries, then again automatically the "charger controller" lowers the voltage so that it is suitable for charging the batteries (BUCK configuration). - It has integrated MCT and MPPT technologies. When the wind speed is low and therefore the rotational speed of the wind turbine is low, then if the generator is subjected to a heavy load, the rotational speed of the turbine will decrease even more, with negative consequences on the overall efficiency of the system. To avoid this problem, the "charger controller" is equipped with two special electronic devices. One monitors the maximum current power (max current tracking - MCT) and the other the instantaneous power (max power point tracking - MPPT). Thus, by having these two pieces of information, it can automatically adjust the amount of load that the generator can be loaded with, without disturbing the overall efficiency of the system. - Ability to connect to a computer. The serial port enables the interface with a computer, not only for data transfer and analysis, but also for setting the operating parameters. |

|

Nominal

power: 45 KW |

| The

gear box is used to increase the rotation speed of the generator. The gearbox has an oil temperature indicator and an oil level indicator. The gearbox housing as well as the special oil filling stage are designed to act as a cooling device. The gearbox can be removed and reassembled on the wind turbine in a simple process. The gear box is designed in such a way that it can accept the shock of a violent braking by the electric brake . |

|

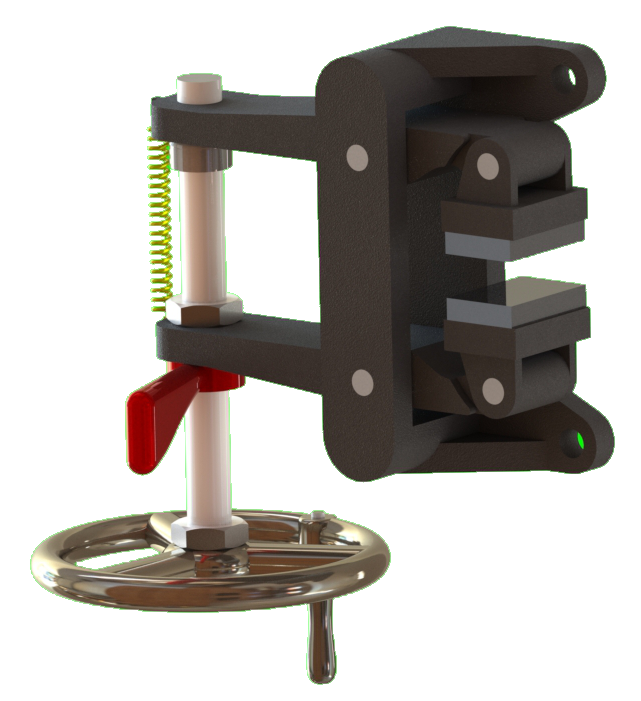

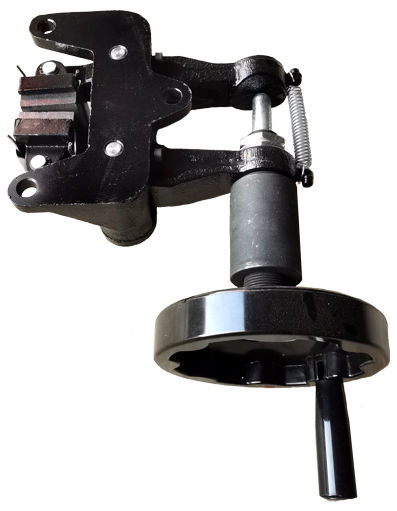

Manual

safety brake. |

Model:

"H7010" |

|

|

The

manual safety brake stops the turbine shaft. It works by manually rotating

an endless shaft which tightens the two calipers that fit into the brake

disc |

|

|

Digital

anemometer. |

Model:

"H8008" |

|

|

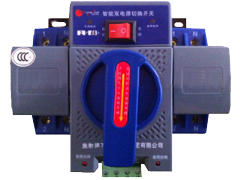

Automatic

change-over transfer switch. |

Model:

"H8021" |

| Used

so that the user can freely choose each time the source of electricity.

Wind turbine or grid. |

||

|

|

|